Printing business product packaging will firstly protect the interests of consumer while the market has real and fake goods is mixed. With full information on the packaging, customer can choose for themselves the original products, avoiding buying fake and poor quality goods.

One of the meanings of packaging is to deliver information. The information printed on the packaging includes: manufacturer information, product name, ingredients, raw materials, functional uses, etc. In addition, the packaging is also used as a marketing tool of the business, or to check product quality through product code.

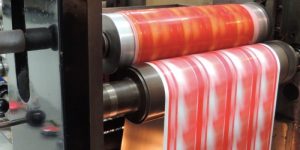

Understanding that need, NeosysVietloi introduced to the market of tapes for bundling machines with printed information for customers. Tape for bundling machine is a new one of packaging used by many businesses. Putting business and product information on the tape is a must. Helping businesses promote official information to consumers. On the other hand, it helps businesses control production and save costs if they are managed according to product code.

Depending on the design and requirements from the customer, the printing will be different and the printing technology will be also different. Printing on tape for bundling machines can be summarized as follows:

1. Gravure printing

Printing technology uses gravure axis with a thickness of about 10 microns, the printed elements (writing letters, images) are deeply engraved and located below the surface of the print axis, the non-printed elements will be on the surface of the print axis. . This printing method is quite complicated, so the principle of operation takes place in 2 processes.

+ Stage 1: Ink is supplied to the surface of the printing mold. Next, people will dip the gravure axis into the ink trough. And of course, there will be ink fill into the recesses of the print element.

+ Stage 2: The ink in the non-printing element will be wiped away by the ink knife, then the ink only contained in the concave holes (printing element) will be transferred to the surface of the printed material thanks to high printing pressure and stick with material.

Gravure printing can print on all different materials for sharp image quality, fast printing speed, suitable for printing in large quantities but high investment costs.

2. Flexo Printing

Direct printing method, can be used on many different surfaces and materials such as paper, decal, fabric, metal film, nylon, glass, corrugated iron, steel, carton… The most popular technology used in production today.

The difference between flexo and other techniques is in the principle of ink supply and image creation. Accordingly, ink will be supplied to the printing mold thank to anilox shaft (metal shaft) with a concave engraved surface. When printing, ink will enter the recesses and print onto the material.

In particular, when using flexo technology, the machine will automatically die right after the printing process. To put it simply, this system has an additional function of taking off excess parts of the product, saving time and optimizing for manufacturers.

Flexo printing can print on any surface including hard, soft, absorbent or non-absorbent. The printing surface is prone to smearing or uneven ink adhesion. Fast printing speed meets high volume printing but high printing cost.

3. Digital Printing

Among printing technologies, digital printing is the most modern type of printing today. This printing method is done digitally, the images are sent directly to the printer and printed out immediately in the required quantity.

The working principle of digital printing is based on the automation of the machine, just need to load the image into the printer, the machine will analyze and process, color and print the product quickly. fast, shorten the time.

Digital printing prints on a wide range of substrates and material thicknesses. Image quality will not be sharp. The slow speed is suitable for low-volume printing and low cost.

Those are 3 methods to print tape for bundling machine. It can be seen that each printing technology has its own advantages and disadvantages. Therefore, businesses must base on their design requirements and choose the printing method that brings the best effect.

We can print the product code (bar code, QR code) on the tape. With using product code helps our business to check and control the production.

This is the important role of printing information on tape to both catch up with the market, keep up with trends and meet the needs of consumers.

If you have any questions or want to refer to the printing on tape for the bundling machine, please visit the website of NeosysVietloi company https://neosystape.com.vn or call the hotline available on the website to answer your questions. .

Product packaging is the face of the product as well as of the brand. Therefore, do not underestimate the role and meaning of packaging. Printing on tape for bundling machines is no exception to that trend.

———————————–

Please contact Neosys Viet Loi immediately for a free consultation:

Hotline : 0902 886 117 (call/ SMS/ Zalo)

Japanese Contact : 0907 401 765

Korean Contact : 0909 735 117

International (SG) : +65-9186-5123

Email: info@neosys-vietloi.com.vn

Address: No.52, Street 17, An Phu Ward, Thu Duc City, HCMC

Website 1: www.neosysvietloi.com.vn

Website 2: www.neosystape.com.vn

Facebook: Fanpage Neosysvietloi

It’s our pleasure to serve you